A manual transaxle diagram is a visual guide illustrating the components and their relationships within a manual transmission system․ It aids in understanding, maintaining, and repairing the transaxle, a crucial part of the vehicle drivetrain․ These diagrams are essential for technicians and enthusiasts to diagnose and address issues like gear problems or synchronizer wear․ By detailing gears, bearings, and clutch systems, they provide a clear blueprint for troubleshooting and ensuring smooth gear shifting․

What is a Manual Transaxle?

A manual transaxle is a component that integrates a manual transmission and differential into a single unit, designed for transferring power from the engine to the wheels․ It enables drivers to manually shift gears using a clutch pedal and shift lever, providing control over speed and torque․ The transaxle contains gears, bearings, and synchronizers, which work together to facilitate smooth gear changes․ This system is commonly found in rear-wheel-drive vehicles and is essential for efficient drivetrain operation, allowing precise control over gear ratios for optimal performance․

Importance of Understanding Manual Transaxle Diagrams

Understanding manual transaxle diagrams is crucial for diagnosing and repairing transmission issues, as well as for routine maintenance․ These diagrams provide a clear visual representation of the transaxle’s components, such as gears, bearings, and synchronizers, allowing technicians to identify and address problems efficiently․ For enthusiasts and mechanics, this knowledge enhances troubleshooting capabilities, ensuring that repairs are done correctly and safely․ By studying these diagrams, one can gain a deeper understanding of how the transaxle operates, enabling better maintenance and extending the lifespan of the vehicle’s drivetrain․

Components of a Manual Transaxle

A manual transaxle consists of gears, bearings, a clutch, and synchronizers, working together to transmit power and enable smooth gear shifting in a vehicle’s drivetrain system․

Transmission Case and Bearings

The transmission case serves as the housing for all internal components, providing structural integrity and protection․ Bearings are crucial for reducing friction between moving parts, ensuring smooth operation․ They are strategically located to support gears and shafts, minimizing wear and tear․ Proper lubrication of bearings is essential to prevent overheating and premature failure․ In the provided information, there are references to removing bolts from the front transaxle case, indicating that access to these components is necessary for maintenance or repair․ Bearings and seals must be inspected regularly to maintain optimal performance and prevent damage to the transaxle․

Gears and Gear Ratios

Gears within a manual transaxle are toothed wheels that mesh to transmit power and adjust speed/torque ratios․ Gear ratios vary to optimize performance across driving conditions․ The internet data highlights issues like stuck gears and synchronizer problems, emphasizing the importance of proper gear engagement․ Double-declutching, though noisy, ensures smooth shifting in older systems․ Modern designs focus on quieter, more refined operation․ Gears are precision-engineered to withstand stress, with ratios tailored for specific vehicles․ Understanding gear ratios is key to diagnosing issues like harsh shifting or difficulty engaging gears, often linked to worn components or misalignment․ Regular maintenance is critical to ensure longevity and smooth operation․

Clutch and Pressure Plate

The clutch and pressure plate are essential components in a manual transaxle system, enabling smooth gear transitions by engaging and disengaging power from the engine to the transmission․ The clutch disc, sandwiched between the pressure plate and flywheel, facilitates this connection․ When the clutch pedal is pressed, the pressure plate releases its grip on the disc, allowing gear shifts without grinding․ Proper alignment and adjustment of the clutch system are critical to prevent wear and ensure seamless operation․ Issues like slipping or sticking can arise from worn or misaligned components, requiring inspection and maintenance to restore functionality and prevent further damage to the transaxle․

Shift Forks and Synchronizers

Shift forks and synchronizers are critical components in a manual transaxle, enabling smooth and precise gear transitions․ Shift forks are levers that move the gears into position, while synchronizers ensure that the gears mesh properly by equalizing their speeds during shifting․ When the driver presses the clutch and moves the shift lever, the fork engages the synchronizer, which then aligns and meshes with the desired gear․ This mechanism prevents grinding and ensures seamless shifting․ The synchronizer hub and springs play a key role in this process, making manual shifting efficient and driver-friendly․ Proper functioning of these parts is essential for smooth transaxle operation and longevity․

How a Manual Transaxle Works

The manual transaxle operates by disconnecting the engine from the transmission via the clutch, allowing the driver to manually select gears using the shift lever and synchronizers․

Basic Operating Principle

A manual transaxle operates by disconnecting the engine from the transmission via the clutch, enabling the driver to manually select gears․ When the clutch pedal is pressed, it disengages the engine from the transmission, allowing the driver to shift gears using the shift lever․ The gears inside the transaxle are designed to provide different speed and torque ratios, enabling the vehicle to accelerate efficiently at various speeds․ The synchronizers ensure smooth gear engagement by matching the speed of the gears before they mesh․ This process allows the vehicle to transition between gears seamlessly, maintaining control and performance․

Role of the Clutch in Gear Shifting

The clutch plays a critical role in gear shifting by disconnecting the engine from the transmission․ When the driver presses the clutch pedal, it disengages the engine’s power, allowing the transmission to shift gears without grinding or damage․ The clutch consists of a friction plate, pressure plate, and release bearing․ As the pedal is pressed, the release bearing moves to separate the friction plate from the flywheel, interrupting power flow․ This temporary disconnection enables smooth gear transitions․ Proper clutch operation is essential for efficient shifting, as it prevents wear on synchronizers and gears, ensuring prolonged transmission lifespan․

Function of Synchronizers

Synchronizers are essential components in a manual transaxle, ensuring smooth gear transitions․ Their primary function is to synchronize the speed of the gear and the shaft before engagement, preventing grinding or damage․ When the driver selects a gear, the synchronizer collar aligns with the desired gear, matching their rotational speeds․ This is achieved through a friction mechanism that temporarily locks the gear to the shaft, facilitating seamless engagement․ Synchronizers improve shifting precision, reduce wear on gears, and enhance overall transmission efficiency, making manual driving more fluid and reliable․

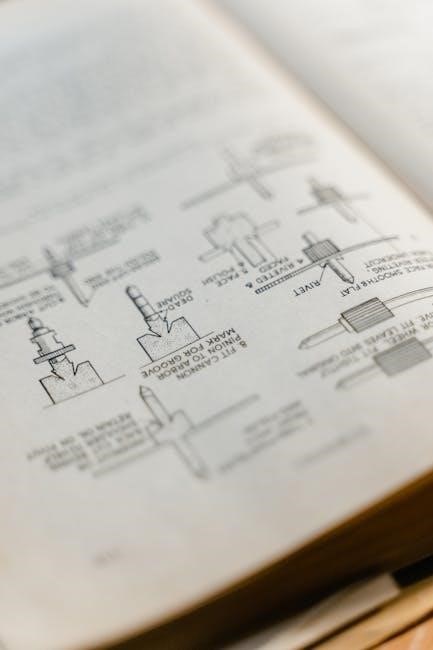

Manual Transaxle Diagram: Key Elements

A manual transaxle diagram highlights gears, shafts, bearings, seals, and the shift linkage system․ These elements are clearly identified, showing their interconnections for proper diagnosis and maintenance․

Visual Representation of Gears and Shafts

A manual transaxle diagram provides a detailed visual layout of gears and shafts, showcasing their arrangement and connections․ The diagram illustrates how drive shafts connect to gear sets, enabling power transfer․ Gears are typically color-coded or labeled to indicate their functions, such as input, output, and idler gears․ This clarity helps in understanding gear ratios and mechanical relationships․ The visual representation also highlights how shafts rotate and interact, simplifying the identification of components for maintenance or repair․ This feature is essential for mechanics and enthusiasts to comprehend the internal workings of the transaxle system effectively․

Location of Bearings and Seals

In a manual transaxle diagram, bearings and seals are strategically located to ensure smooth operation and prevent wear․ Bearings are placed at critical points, such as the input and output shafts, as well as between gear sets to reduce friction․ Seals are positioned at the ends of the transmission case to prevent lubricant leakage․ The diagram highlights these components, often using arrows or color-coding to indicate their placement․ Understanding their locations is vital for maintenance and repair, as it allows technicians to identify potential failure points without disassembling the entire transaxle․

Shift Lever and Linkage System

The shift lever and linkage system in a manual transaxle diagram connects the driver’s gearshift to the transmission․ It includes the shift lever, linkage rods, and joints that transfer the driver’s input to the transaxle․ The system ensures precise gear engagement by moving the shift forks, which align gears with synchronizers․ Proper alignment and lubrication of the linkage are crucial for smooth shifting․ Wear or misalignment can lead to difficulty in changing gears, highlighting the importance of regular maintenance․ The diagram illustrates this system, showing how each component interacts to facilitate seamless gear transitions․

Shifting Techniques for Manual Transaxle

Mastering smooth acceleration and gear transitions is essential for optimal performance․ Techniques include gradual clutch release, matching engine speed to gear selection, and avoiding riding the clutch․

Double-Declutching Technique

Double-declutching is a traditional shifting method that ensures smooth gear transitions, especially in older vehicles without synchromesh gears․ The process involves pressing the clutch pedal, shifting into neutral, releasing the clutch, and then depressing it again to engage the desired gear․ This technique prevents grinding gears by matching the engine speed to the transmission speed․ It requires precise timing and coordination between the clutch pedal, accelerator, and gearshift․ While modern manual transaxles often have synchromesh gears, double-declutching remains a valuable skill for driving classic cars or vehicles with non-synchronized transmissions․ It enhances control and reduces wear on transmission components․

Proper Use of the Clutch Pedal

The clutch pedal is a critical component in manual transaxle operation․ Its proper use ensures smooth gear transitions and prevents damage to the transmission․ To use the clutch correctly, press it fully down before shifting gears to disconnect the engine from the transmission․ Avoid “riding” the clutch, as this can wear down the clutch assembly․ When shifting into gear, release the pedal gradually while applying light throttle to ensure a smooth engagement․ Proper clutch technique reduces wear on the pressure plate and flywheel, extending the lifespan of the manual transaxle․

Common Manual Transaxle Diagrams

Manual transaxle diagrams vary, with 4-speed, 5-speed, and 6-speed being the most common․ They typically depict gear layouts, shafts, bearings, and shift linkages for specific transmissions․

5-Speed Manual Transaxle Diagram

A 5-speed manual transaxle diagram illustrates the components and layout of a five-speed transmission system․ It typically includes the gear sets, input and output shafts, and the shift linkage mechanism․ The diagram shows how the gears are arranged in a specific pattern, with each gear ratio labeled for clarity․ It also highlights the engagement points and synchronizers, which facilitate smooth gear transitions․ This visual guide is essential for understanding how power is transmitted through the gears and how the shift fork engages each gear․ By studying the 5-speed manual transaxle diagram, one can better comprehend the mechanical relationships and maintenance requirements of the system․

- Gear Sets: Shows the arrangement and ratios of the five forward gears and reverse gear․

- Shift Linkage: Details how the shift lever connects to the transmission․

- Synchronizers: Illustrates their role in aligning gears during shifts․

4-Speed Manual Transaxle Diagram

A 4-speed manual transaxle diagram provides a detailed visual representation of a four-speed transmission system․ It outlines the layout of gears, shafts, and other components, showing how they interact during gear shifts․ The diagram typically includes the transmission case, gear sets with specific ratios, and the shift mechanism․ It highlights the engagement points and the flow of power from the input shaft to the output shaft․ This diagram is crucial for understanding the mechanical operation and for performing repairs or maintenance․ It also illustrates the reverse gear setup and the role of bearings and seals in ensuring smooth operation․

- Gear Sets: Displays the arrangement of four forward gears and one reverse gear․

- Shift Mechanism: Shows how the shift fork engages gears through the synchronizer․

- Bearings and Seals: Indicates their locations to ensure proper lubrication and prevent leakage․

Maintenance and Repair

Regular maintenance ensures optimal performance and longevity of the manual transaxle system․ Inspect fluid levels, check for leaks, and replace worn components promptly to prevent damage․

- Fluid Checks: Essential for lubrication and smooth gear operation․

- Gasket Inspections: Prevents leaks and maintains system integrity․

- Component Replacement: Addresses worn gears or bearings before failure․

Routine Maintenance for Manual Transaxle

Regular maintenance is essential to ensure the longevity and smooth operation of a manual transaxle․ This includes inspecting gear teeth for wear, checking bearings for smooth rotation, and ensuring all seals are intact to prevent fluid leaks․ The clutch pedal should be checked for proper alignment and free play, while the shift linkage system must be clean and lubricated to avoid sticking or difficulty in shifting gears․ Additionally, periodic fluid changes are crucial to maintain lubrication and prevent overheating․ Referencing a manual transaxle diagram can help identify these components and ensure maintenance is performed accurately․ Regular inspections can prevent major repairs․

Common Issues and Troubleshooting

Common issues with manual transaxles include difficulty shifting gears, noisy operation, and fluid leaks․ These problems often stem from worn-out components like synchronizers, bearings, or seals․ Troubleshooting involves inspecting the gear teeth for wear, checking synchronizer engagement, and verifying fluid levels․ Noisy gears may indicate worn teeth or insufficient lubrication․ Leaks can occur around seals or gaskets, requiring replacement․ Referencing a manual transaxle diagram helps identify and locate faulty parts․ Regular inspections and timely repairs can prevent these issues from escalating, ensuring smooth and efficient transmission performance․ Always consult the diagram for precise disassembly and reassembly guidance․

Manual Transaxle Repair Guide

A manual transaxle repair guide provides step-by-step instructions for fixing issues, using diagrams to identify components and ensure proper reassembly․ It’s essential for DIY mechanics to follow it carefully to avoid further damage and ensure smooth operation․

Disassembly and Reassembly Process

The disassembly and reassembly of a manual transaxle require precision and patience․ Begin by draining the lubricant and removing external components like the shift lever and clutch․ Next, detach the transaxle from the engine, ensuring all bolts are removed․ Internal components such as gears, bearings, and shafts must be carefully extracted, referencing the manual transaxle diagram for clarity․ During reassembly, align parts according to the diagram, ensuring proper seating of bearings and gears; Tighten all bolts in the specified sequence to avoid damage․ Marking components before disassembly helps simplify the reassembly process․ Always refer to the diagram to confirm correct placement of each part․

Replacing Worn-Out Parts

Replacing worn-out parts in a manual transaxle is crucial for maintaining smooth operation․ Use the diagram to identify components like gears, bearings, or synchronizers that show wear․ Always replace parts with genuine or compatible alternatives to ensure proper fitment․ Tools like gear pullers and presses may be needed for removal and installation․ Refer to the manual transaxle diagram for torque specifications and reassembly sequences․ Properly align and secure parts to avoid further damage․ Testing the transaxle after replacement ensures all components function correctly․ Addressing worn parts promptly prevents additional damage and extends the transaxle’s lifespan․

Understanding manual transaxle diagrams is essential for effective maintenance and repair․ This knowledge empowers drivers to identify and address issues, ensuring optimal performance and longevity․

A manual transaxle diagram provides a detailed visual and functional understanding of the transmission system․ It highlights key components like gears, bearings, and the clutch, explaining their roles in power transmission․ The diagrams illustrate how gears interact and shift, emphasizing the importance of synchronizers and shift forks․ Proper interpretation of these diagrams aids in maintenance, troubleshooting, and repair․ They also reveal the linkage system and how it connects to the shift lever, ensuring smooth gear transitions․ Understanding these elements is crucial for diagnosing issues and ensuring optimal performance, making manual transaxle diagrams an invaluable resource for both drivers and mechanics․

Final Thoughts on Manual Transaxle Diagrams

Manual transaxle diagrams are an essential tool for understanding and maintaining transmission systems; They empower drivers and mechanics to diagnose issues, perform repairs, and optimize performance․ By simplifying complex mechanisms, these diagrams make it easier to grasp how components interact․ Whether for routine maintenance or troubleshooting, they provide clarity and confidence․ For enthusiasts and professionals alike, manual transaxle diagrams are a gateway to deeper knowledge and control over their vehicles․ They not only enhance DIY capabilities but also foster a better connection between the driver and the machine, ensuring longevity and efficiency in operation․